Thermal Performance of Tiny House Subfloors

We explore the thermal performance of five common tiny house subfloor construction methods. Like most things, there are trade-offs and multiple approaches to consider., what’s the best way to construct your tiny house subfloor? This post continues the discussion from a previous post.

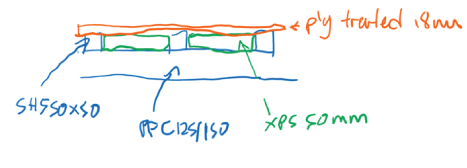

1. 50mm XPS between steel joists R1.3

2. 70mm XPS between joists, 20mm timber thermal break on joists R1.9

4. 7mm ply under layer, 90mm LVL joists, 90mm earth wool between R2.6

3. 70mm PU between joists, 20mm timber thermal break on joists R2.0

5. 7mm ply under layer, 40mm timber joists, 40mm XPS between R1.6

Construction methods

Is the common approach for tiny house subfloor construction in NZ. Because its cheap, lightweight and minimises height. In terms of thermal performance its poor at only R1.3.

Is a similar approach to 1 but added a cheap and simple thermal break and increased insulation thickness. Adds a little more cost, height and weight compared to 1 but increases R value by almost 50% to R1.9.

Same setup as 2 buy uses PU insualtion which has a higher r value than XPS. An increase of R0.1 which is not great for in most cases a more expensive and harder to get material compared with XPS. Also need to be cautious about the higher global warming potential blowing agents in certain PU foams.

Is sandwich construction that utilises timber for the structure and does not rely on steel. This system jumps to R2.6 which achieves current minimum building code for some zones.

Similar to 4 but a thinner sandwich construction sitting on steel joists. The 40mm of insulation reduces the R value to R1.6.

What system to we use?

After evaluating various designs and conducting thermal modeling, we lean towards two methods. Option 2 is considered a good compromise between weight, cost, height, and thermal performance. Option 4, effectively reduces trailer costs, making it appealing for DIY enthusiasts or builders. The total weight is comparable to option 2, with a slight reduction in height. While the costs are similar, the improvement in thermal performance, with an R0.7 increase, is significant. The Smart Trailer Basic utilises option 4.

Assumptions

Plywood floor 18mm

Joist spacing 600mm

DPC between the steel and timber

Insulation is tightly fitted

Abbreviations

LVL - Laminated veneer lumber (dense and strong timber)

XPS - Extruded polystyrene sheet (insulation)

PU - Polyurethane (insulation)

PFC - Parallel flange channel (steel)

SHS - Square hollow section (steel)

DPC - Damp proof course (barrier)

The minimum building code for suspended floors has increased to R2.5-3, depending on the climate zone, up from R1.3. We prioritize maximizing insulation wherever possible, but as previously mentioned, compromises must be made a mobile tiny house. Factors such as weight, height, cost, and width all play a role. While achieving an R-value of 3 for floor is thermally advantageous, it may impede of these other considerations.

Thermal modelling was conducted by Jason Quinn at Sustainable Engineering.